Final product assembly in our plant

Our manufacturing facility focuses on Medical & Healthcare products, especially those that require integration of multiple manufacturing processes, such as PCBA, plastics & metal, wire harness and cut & sewn of soft materials.

Capabilites:

- Turnkey electro-mechanical products and sub-assemblies

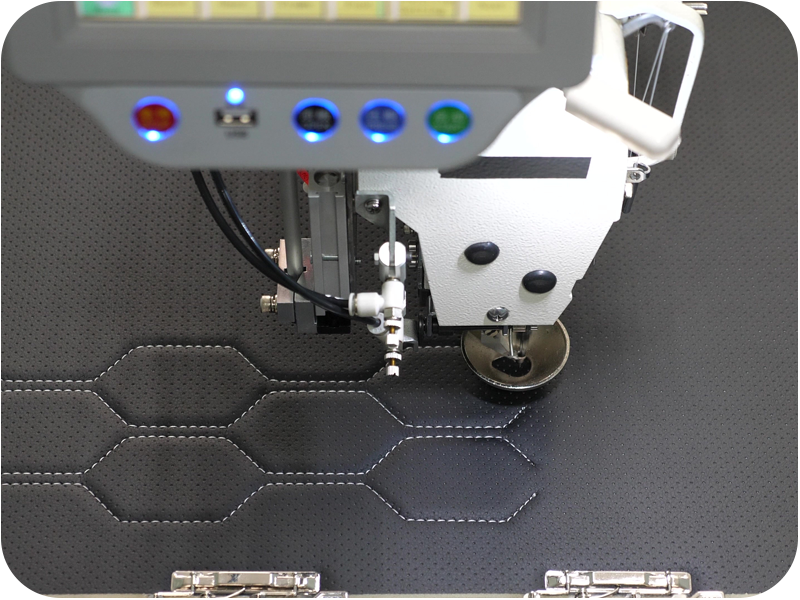

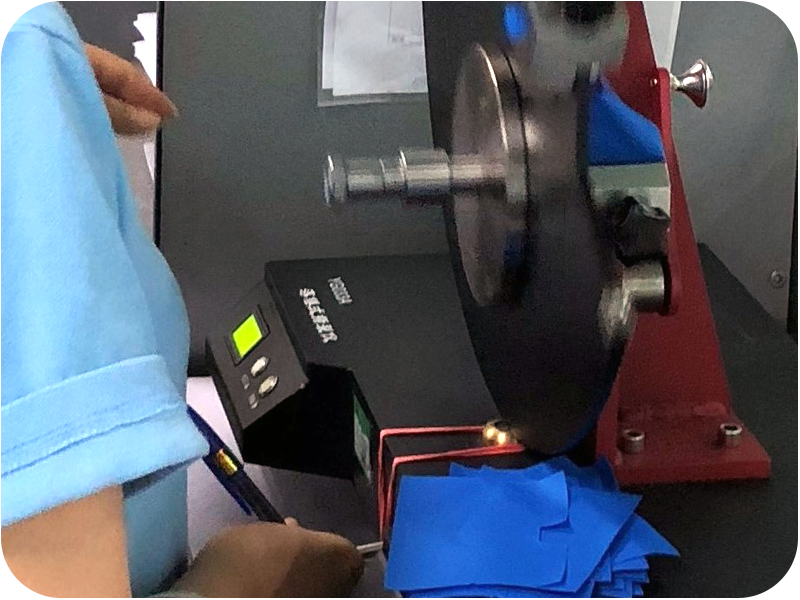

- Soft goods, cut & sewn and RF welding products

- Sewn products and soft goods design and engineering

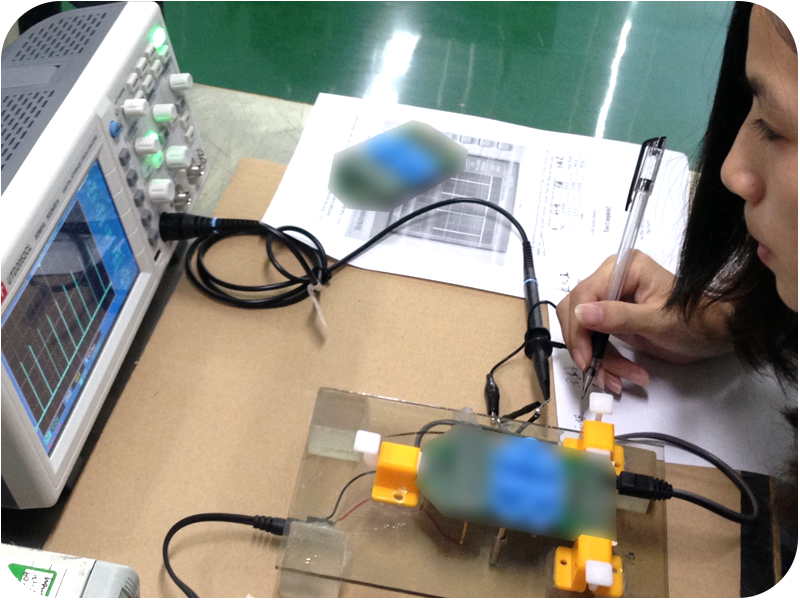

- PCB assemblies, both SMT and Thru-hole components

- Wire harness

- Injection and compression molding of a wide range of resins

- Metal stamping and forming

- Die casting and Investment casting

- Precision machining

- Various secondary processes: plating, painting, printing etc.

We arrange certain primary processes, components or sub-assemblies, through our proven supply chain of partner plants, to leverage their expertise and economy of scale.

Additionally, we have the flexibility, background and expertise

to augment our established processes with the addition of new manufacturing processes, techniques, and equipment to serve your complete production needs. We are a full-service comprehensive manufacturing operation with a proven track record of meeting our customers’ production goals.

We can provide you a turnkey solution to your complete products, or any combination of your sub-assemblies.